Canadian owned and operated

Miller® PipeWorx 400 Welding System Package 230/460V

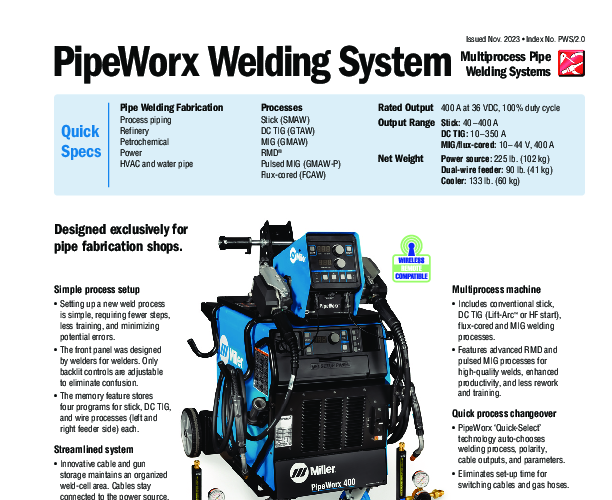

Simplified and optimized for pipe fabrication shop welding, the PipeWorx systems streamlined set-up with one touch welding, quick process changeover, and Pulsed and Modified Short-Arc MIG processes, makes training and turn-around times faster than ever before.

Simple Process Setup: Clearly labeled controls in easy-to-understand welder terminology. Requires just a few basic steps to set up a new weld process, resulting in less training time and minimizing errors from incorrect setups. The front panel was designed by welders for welders. Only backlit controls are adjustable to eliminate confusion. Memory feature stores four programs for each selection: Stick, DC TIG, and MIG (left and right side of feeder). Beneficial when using multiple procedures, multiple process parameters or multiple welders and eliminates the need to remember parameters. Quick Process Changeover: No need to manually switch polarity or cables and hoses between processes. Simply push a process selection button to choose a welding process. PipeWorx 'Quick-Select' technology automatically selects the welding process, the correct polarity, cable outputs and welding parameter. Quick process changeover eliminates set-up time for switching cables and gas hoses. Also, reduces the risk of weld reworks due to incorrect cable connection. Multiprocess Machine: Weld processes are optimized to deliver superior arc performance and stability specifically for root pass, fill and cap pipe welding. Includes conventional Stick, DC TIG (Lift-ARC™ or HF Start), Flux-Cored and MIG welding processes. Also features the advanced RMD® and Pulsed MIG processes that deliver superior quality welds, increase productivity, and reduce rework and training. Streamlined System: Wind Tunnel Technology™ and Fan-On-Demand™ provide system protection in the dusty shop environment. Innovative cable and gun storage manages clutter for a cleaner, organized weld-cell area. Cables remain connected to the power source and do not need to be switched for the different welding processes. All system components have been selected to meet the needs of a pipe fabrication shop.| Additional Information |

|---|

| Packaging Description:1 Per Ea |